Profile

Louise Wood

I'm prepping for tomorrows visit to test extraction systems in a Quarry in North Wales

Curriculum Vitae

-

Education:

St Johns First and Middle Schools. Harry Cheshire High School where I completed GCSE’s and A/S levels. Kidderminster college to study childcare. I have done independent Engineering courses in LEV Testing, design, commissioning and Occupational Hygiene.

-

Qualifications:

I got GCSE grades B in Resistant Materials, English, Maths, Double Science, French, Geography & Music. A/S & A level grade A in Maths & English and a B in Physics. I have a BTEC in Childcare. A NVQ level 5 in Customer services. I hold the full suite of BOHS P-Cert qualifications in LEV; P601, P602, P603, P604 & W201. Also an approved tutor to teach all these BOHS courses. I also have lots of certificates and licenses for working safely on site; including; driving forklifts, cherry pickers and scissor lifts.

-

Work History:

At 16 I had a Saturday job at Bodycare in Kidderminster town centre. I moved onto TJ Hughes which was a department store in town, I worked in the Men’s clothes department 4 days a week. I also had an evening cleaning job for a local engineering firm, I used to go straight there after my shift at TJ’s. I left TJ’s for a couple of weeks chasing a more money, I tried being a Teletext holiday sales agent. It was the most rubbish job in the world, they kept rising your target every week so that you never earned the commission as advertised. I lasted there a couple of weeks before going back to TJ Hughes. Then I moved onto The Range Superstore full time whilst doing night school, I was Supervisor of the DIY department. I left the Range 17 years ago and have been working for my dad ever since.

-

Current Job:

LEV Engineer

-

Employer:

My employer is my dad. He started this company before I was even born in 1980. I actually never imagined I’d be working for my dad even though I have so many happy memories going to site with him as a young child. Life was different when I was a kid compared to now. Health and Safety wasn’t as stringent as it is now. I was allowed to go to various sites with him, as a young girl. I have happy memories of helping various people on the clients sites whilst my dad went off to measure the job and I was in my element.

- I was allowed to pack crisps at Red Mill snack foods and they gave me a box of crisps as thanks.

- I was allowed to take out the chess pieces at a place that injection moulds plastics.

- I filled a machine that made bin bags with plastic beads.

I think those early experiences have helped me a lot. I remember sitting in the careers office at 15 and the lady asking questions about dad and his business. Its hard to figure out what you want to do for the rest of your life but I never had considered working for my dad. I wanted to be a teacher and that was it.

How it all began:

When I was working at The Range, my dad wasn’t well at all. He asked if id help him on a day off and I did. I enjoyed it. After that working with dad on days off became a regular thing, even after they diagnosed his rare form of Leukaemia and managed it with medication. I had secured a management position at The Range which I was so proud of and so excited about. The day before my official promotion the store manager called me in the office to tell me that they aren’t promoting me as I work too hard and they cant afford to lose me off the shop floor. I was devastated and went home in tears. Dad suggested I work for him. On the day I should have been promoted, I handed my notice in. A week later I was working for Airducts.

I’ve been here 17 years now. Its challenging but I get a kick from every time we achieve something and the customer is happy.

Our Logo

-

About Me

I'm a dog momma, lego mad, astronomy photographer, craft loving geek

-

Read more

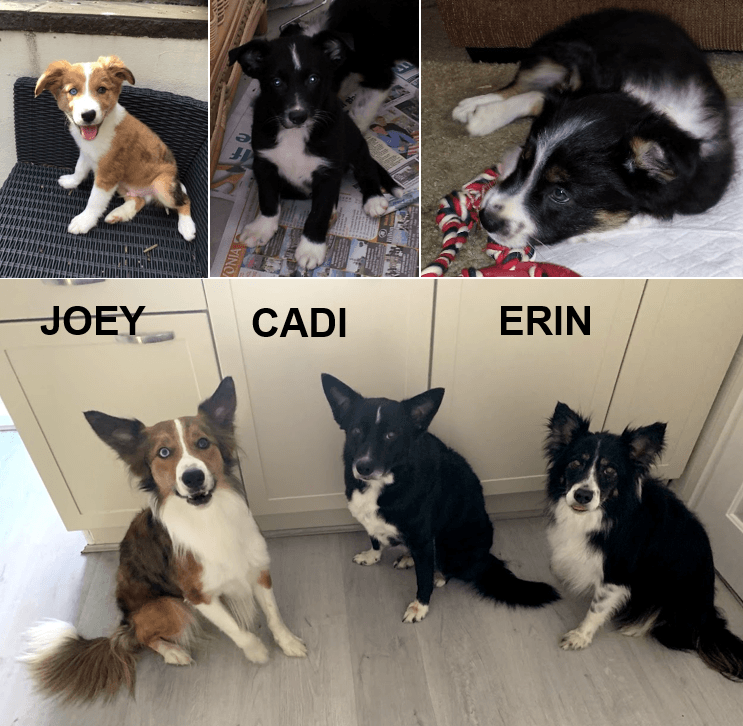

I am 38 and live in Worcestershire. I have 3 spoilt dogs, all border collies and they are such lovely dogs. Their names are Cadi, Erin and Joey. Cadi and Erin are 9 years old and Joey is 2.

Figure 1. Showing my dogs Cadi, Erin and Joey now and when they were puppies.

I enjoy cooking meals from scratch. I like to do arts & crafts in the little spare time I have; make candles, bathbombs, soap and sew household things such as cushions & curtains. I used to be a well known designer for sewing magazines and I won awards for my designs. I do craft fairs and sell my art and other home made gifts.

I’m a bit of a Astro geek. I spend hours in the garden observing our moon, planets, stars and galaxies (when I should be sleeping for work – sssssshhhhh 😊). I’m not very good but I like to photograph the moon, planets and galaxies.

Figure 2. A picture of the Super moon I took on the 25th May 2021. A picture of the galaxy NGC 1309 taken on 5th April 2021

I enjoy building Lego and have built all the space sets; the Apollo 11 Lunar lander, the Apollo 11 rocket, the discovery shuttle and the International Space station.

Figure 3. My LEGO international Space Station.

I am a book worm. I love reading books on Space and Quantum Physics, don’t always understand all elements of Quantum Physics but it makes me think really hard and I like that. I listen to podcasts every day. My work means long hours driving and so I enjoy listening to series of Podcasts. I like the Nasa podcasts the most. I am currently listening to a BBC Podcast called Death in Ice Valley, which I’m really enjoying.

-

My Work

I’m a hands on Incorporated LEV Engineer. Designing, building & fixing systems which suck away dusts and fumes to stop people breathing them in and getting poorly.

-

Read more

I’m an Incorporated Engineer specialising in Local Exhaust Ventilation, called LEV for short. It’s basically a hoover but on a mega industrial scale.

Most factories in the UK make all sorts of wonderful things but unfortunately the process of making things produces dusts and fumes. Just some examples:

- Quarries blasting out stone & slate produce silica dust.

- Welding produces fume.

- Plastic bag manufacturers produce polymer fumes.

- Wood working produces wood dust.

These dusts and fumes are bad for the lungs if you breathe them in. Because they are bad for your health they are governed by the CoSHH Regulations. CoSHH is short for the Control of Substances Hazardous to Health. What we do is prevent people breathing in the dusts and fumes by adding extraction to suck away the dust and fumes. In doing so we are complying with the CoSHH Regulations and Pollution control set by the Environmental Agency.

You may have some LEV extraction in your school if you have a woodworking classroom. If you have any fretsaws, band or disk sanders then that produces wood dust. You should have some sort of extraction that sucks away the dust.

Summary of what we do as a company

I work for my dad. Our base is a small factory in Droitwich in Worcestershire.

Figure 4. Picture of our factory (my van is the middle one)

A brief summary of our companies services:

Design.

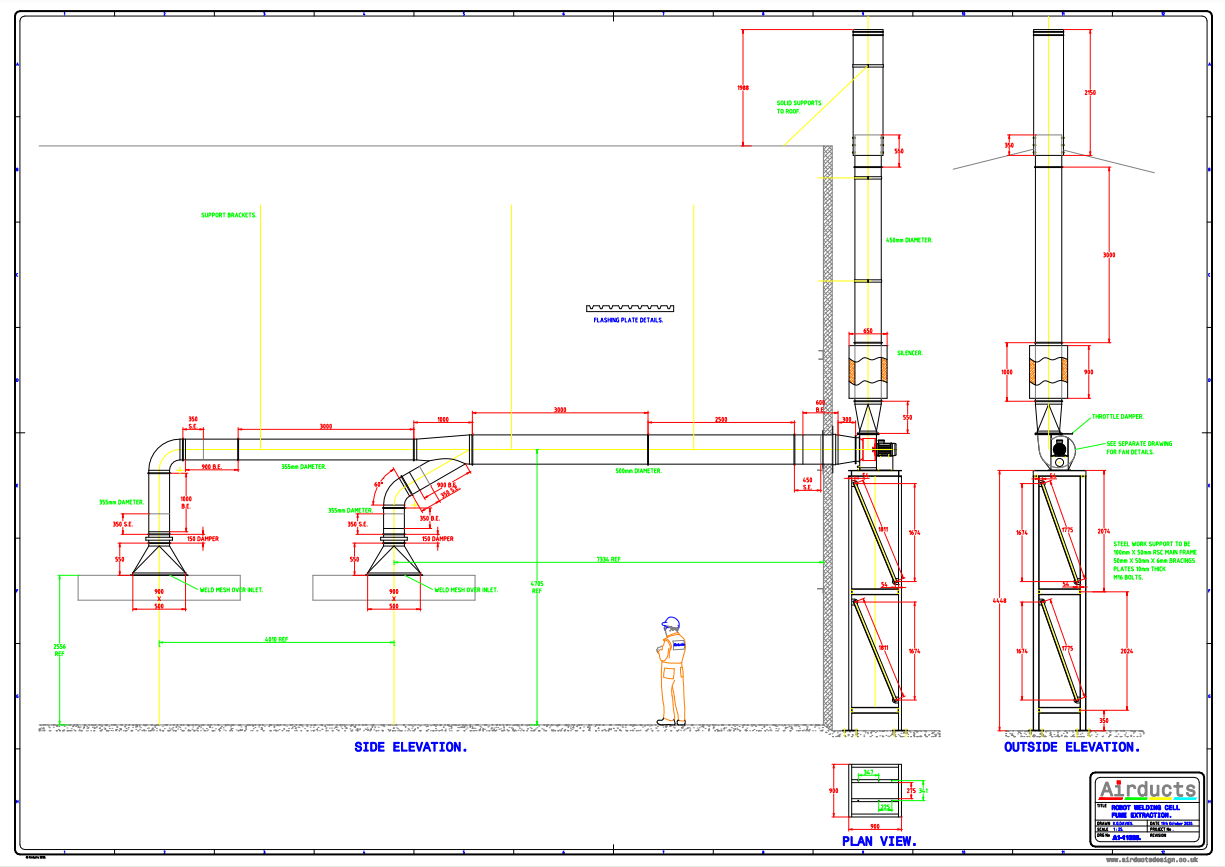

We firstly have to tell our guys in the factory what to make. We do this by doing design work. Our customer rings us with a problem. We go to see the customer, look at their problem and use our skills and knowledge to produce a solution.

By solution we mean an extraction system suitable for their industrial process for the dust produced from the making process. We send our customer a quotation with a specification detailing our proposal, which normally includes outlining a design using maths (maths is very important). We then put together a costing for making, installing and testing. If successful, then we will get a purchase order to do the work. Then we will go to see the customer again, only this time we measure up the area in detail. These measurements are used to put our design into an AutoCAD drawing. We send the drawing to the customer and if they approve the design then we move onto making.

Figure 5. Showing a typical CAD Drawing.

Make.

We manufacture mainly from sheet metal, with some engineering structural steels for making support brackets.

Figure 6. Inside our factory

The sheet metal is delivered on pallets in flat sheets. These sheets are cut to size dependant upon what we are making, we use a CNC plasma cutting machine to cut out shapes of what we need to make.

Figure 7. Our CNC Plasma cutting machine cutting out patterns.

Figure 8. My dad welding.

Once the material has been cut out we then use other machines such as rollers and hammers to shape the piece. We also use welding and lock forming to join the material and secure our pieces.

Once we’ve made the pieces, they look like this (bit like a lego kit waiting to be built):

Figure 9. Some of the parts we’ve made.

Installation.

All those bits we made are sent on a lorry to the site ready for our fitting team to install. Installation for me is the best bit. You see your design and CAD drawing come to life. Installation includes many risks such as working at height. We hire in machines to help with the task. Forklifts and cranes to help with the lifting. Cherry pickers and scissor lifts for safe working at height.

Figure 10. Crane lifting the ductwork into position

Figure 11. My little brother driving a telehandler (like a forklift) lifting smaller sections of duct up onto the roof.

Figure 12. Crane lifting a filter unit together.

Test.

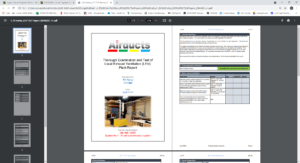

Once the system has been electrically wired up and is working. We test the system and take measurements (mainly the wind speed in the pipe and pressure) to make sure it is working as we designed. If it isn’t we then have to find out why not and fix it so that it does work. We then type our findings into a report for the client in compliance with the CoSHH Regulations.

Figure 13. This is a manometer used to measure the speed and pressure inside a duct (pipe)

-

My Typical Day: I don't actually have a typical day. No two days are ever the same. That is because we are such a small company and you have to have many skills and do alot of things yourself. We don't sell a standard product, we design solutions to fit the clients problem and work environment. So no two systems that we provide are ever the same either. - If I'm at the factory then I get there for 7.30am and leave about 5pm. - If I'm on a clients site then I aim to arrive for 7.30. How early I have to leave my house depends upon how many hours the drive is. I'm a bit naughty in that I don't like to stop for breaks. I like to work as hard as possible to get home as early as I can. My role includes: - - managing the projects at every step. - computer work; quotes, specifications, booking site work, answering emergency call outs, report writing and drawing. - Site work; installing, testing and fixing things.

-

Read more

As I said, I don’t really have a typical day. No two days are the same. This is because being a small company, we have to do everything ourselves. There is so much that we do.

A day in the office includes:

- Drafting Risk Assessments.

- Drafting reports.

- Replying to emails.

- Ordering parts.

- Researching and reading up for a particular design.

- Doing calculations for a design.

- Drafting technical drawings.

- Cleaning and tidying my van.

- Looking after my LinkedIn forum called LEV Central.

- Sometimes out in the workshop at my bench if I’ve got practical work to do.

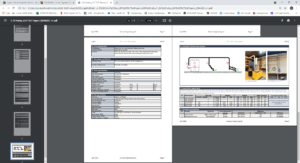

Figure 14. Example of an LEV Statutory test report.

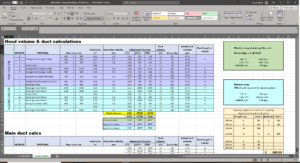

Figure 15. Example of design calculations.

A day on site may include:

- Measuring up for design.

- Statutory testing of LEV systems.

- Personal monitoring (using a pump to measure the amount of dust and fume in someone’s breathing zone)

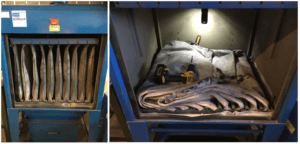

- Changing filters.

- Fault finding, Maintenance; Fixing things and measuring to get parts made.

Figure 16. Servicing a dust filter unit.

Figure 17. I’m up in a cherry picker basket. Recording the speed of the airflow and the pressure. This is part of the statutory testing.

Figure 18. Those filter bags should be white and clean. I took them out and refitted, re doing the seal to fix it.

As a company, we cover the whole of the UK and Ireland. A whole host of different industries including:

- Quarries

- Dockyards

- Education

- Food and Packaging

- Vehicle manufacture and maintenance

- Electronics

- Metal working

- Wood working

- and much more.

Figure 19. I get to work in some really awesome sites. I must admit I do get a bit tired of the travelling and staying away from home sometimes. I do get to see some of our countries great places. Natural and Engineering marvels. So that balances the whole experience out.

-

What I'd do with the money

A collaborative project with students to produce an educational magazine on engineering

-

Read more

I’d use the money towards the publishing of a magazine. I’d like this magazine to be a collaborative project with the students interviewing me to produce an educational magazine on practical engineering to be shared with and made available for schools.

Getting the children involved in the safety and engineering elements and get them to design the graphics. I think it would be a wonderful project. Not only would it enhance their learning but they would benefit from further engagement with an engineer.

-

My Interview

-

How would you describe yourself in 3 words?

dog loving engineer

What's the best thing you've done in your career?

Achieved Incorporated engineer. I fell into this trade by accident and don't have any engineering degrees. I had to do the 'mature candidate' route via my Institute. Type a 70 page technical report and have an interview in London. They don't make it easy so I'm really proud of achieving that.

What or who inspired you to follow your career?

My dad but I fell into this career by accident.

What was your favourite subject at school?

GCSE Resistant Materials. I really loved and excelled at the practical element.

What did you want to be after you left school?

A teacher

Were you ever in trouble at school?

No I was a good student. I worked up from bottom sets up to top sets in school. Top set was too advanced for me, my teachers wouldn't listen and I struggled to keep up. I started to lose interest in school work as a result. I didn't ever behave in a disrespectful way though.

If you weren't doing this job, what would you choose instead?

Rocket engineering. That would be so cool.

Who is your favourite singer or band?

The slow readers club

What's your favourite food?

Roast dinner with all the trimmings, nom

What is the most fun thing you've done?

I've done loads. Its hard to pick one. The Zip Line over the quarry in North Wales.

If you had 3 wishes for yourself what would they be? - be honest!

To not be tired all the time, unlimited lego and to have more time.

Tell us a joke.

What's the best thing about England? Don't know but the Flag is a big plus.(I laughed way too hard at that - sad I know)

-